PATENT PENDING True Universal Automatic Crimp Machine for MILSPEC & Loose Piece Electrical Contacts

“Why can’t you make one machine that just runs everything?”

You asked we listened: after years of development, CDSS is proud to announce our new machine capable of TRUE universal feeding and crimping of loose piece MILSPEC and Machined/Turned electrical contacts (Patent Pending, application number 18/631,492).

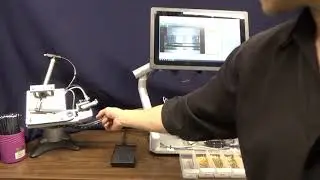

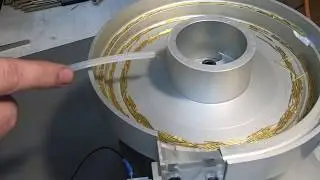

The prototype machine in this video with installed modules, is configured to handle, feed and crimp most contacts in the 26-20AWG range with the Daniels AFM8 Crimp Tool (Guarding is removed to show the crimp mechanism). Use of other contact handling modules will allow this machine to crimp in the full 32-20AWG range of the AFM8 crimp tool. Interchangeable heads with the Daniels AF8 or TE/Deutsch HDT-48-00 combined with additional modules for even more size ranges will allow this one machine to terminate wires from 32-12AWG.

This system brings rapid ROI to high mix/low volume crimping by allowing a single machine to run different contacts as new jobs come in, or if a job uses multiple contacts. Our new UNIVERSAL CRIMPING MACHINE features a series of interchangeable modular mechanisms, each designed to work with a size range of loose MILSPEC/turned electrical contacts. These modules are integrated with an AI machine learning capable "smart" camera system to allow rapid change out between parts by selecting a pre-trained camera program. The camera can be quickly and easily trained to handle new parts: a technician using our template programs can have a new part up and running in minutes.

Prototype machines are in customer testing, production machines will be available in mid/late 2024 and units for integration into fully automated wire processing machines (e.g. Schleuniger/KOMAX) soon thereafter. The UNIVERSAL CRIMPING MACHINE is based on our LC and GWT lines of crimping machines which have been in production and undergoing constant product improvement for over 30 years.

All CDSS products are proudly made in the U.S.A.: Critical parts and mechanisms are machined at our facility in Portland OR, where we also do all design, assembly, testing, and support. Our in-house machine shop enables fast turnaround on repairs and service for our customer's vital production equipment. CDSS offers remote support for setup, maintenance and troubleshooting for all the machines we build at no additional cost.

Learn More @ www.CDavisSystems.com