CDSS LC Crimp Machine for Benchtop Crimping of Multi-Conductor Cable. Machined/Turned Pins & Sockets

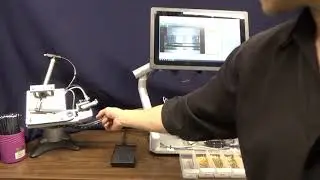

This is a Video of a current 2023 model LC Machine for automated powered crimping of loose machined contacts for use on a benchtop by an operator.

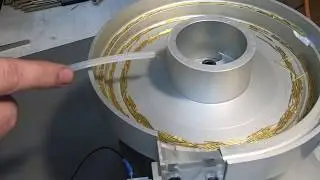

This video shows operation of one of a pair of LC Crimp Machine which was custom ordered by a wire processing company to crimp machined (turned) loose piece pins and sockets via the Daniels AFM8 MILSPEC Crimp Tool. This machine features: a stainless steel slide escapement capable of running a matched pair of PINS AND SOCKETS, a machined aluminum parts bowl, and the CDSS Wire Guide Funnels optimized for best speed of operation in crimping MULTI CONDUCTOR CABLE with short leads.

All current 2023 model LC Machines feature many more integrated sensors than the older models for increased reliability and ease of use by operatiors.

The LC is our "Low Cost" entry to automated crimping of loose or bulk Machined and MILSPEC Electrical Contacts.

Loose contacts are poured into the parts bowl and automatically fed to the crimp head which is built around the proper specified (or MILSPEC) tool to provide automated crimping on pre-stripped wire. The machine is computer controlled via a PLC running our custom software, and requires 110AC and compressed air at 80PSI.

LC Crimp Machines are single bowl benchtop units custom made for a customer's chosen contact. The base model features a cast plastic parts bowl and machined anodized aluminum slide escapements with a tool steel shuttle. The machine in this video was upgraded to a precision machined aluminum bowl and machined stainless steel escapements. Contacts requiring special or complex escapements can likewise be accommodated for an additional cost. Likewise, the new LC Machines can be upgraded with additional features like the Crimphead Contact Sensor in this machine.

The LC machine is very simple and easy to operate -- most Wire Processing Technicians can be up and running with just a few minutes of training.

All CDSS products are proudly made in the U.S.A.: Critical parts and mechanisms are machined at our facility in Portland OR, where we also do all design, assembly, testing, and support. Our in-house machine shop enables fast turnaround on repairs and service for our customer's vital production equipment. CDSS offers remote support for setup, maintenance and troubleshooting for all the machines we build at no additional cost.

Learn More @ www.CDavisSystems.com