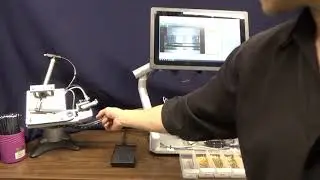

CDSS GWT Compact Crimp removed from Schleuniger CrimpCenter 36 and used as a Benchtop Crimp Machine

This is footage of one of our engineers trying to outrun a Schleuniger CrimpCenter36.

Not really.

We are using a bunch of pre-cut and pre-stripped wires from the Schleuniger machine to demonstrate how the remote head of the GWT Compact Crimp can be used by an operator when removed from the larger wireprocessing machine. And at a pretty good rate too -- he pulled off 25 wire terminations in about a minute for a rate of 2000 PER HOUR! Not so shabby for a benchtop crimping machine. And, as you can see the GWT is faster than the operator.

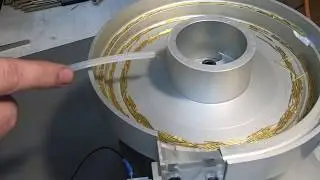

The industry types will notice that the crimphead for this machine is basically a Daniels AF8 MILSPEC Crimp Tool which is being pneumatically actuated and automatically fed by an (offcamera) vibaratory bowl fed parts escapement. Our funnels guide the wire into the contact for extreme speed in operation and then split open for easy retracting of the wire -- it is so easy to operate that a robot can do it.

Please note that this was done as part of testing before shipment of a GWT meant to be integrated into a CrimpCenter36 -- units meant for actual benchtop use always come with a stainless steel guard to protect the operator.

Like everything else we make, this machine was proudly made in the U.S.A.: Critical parts and mechanisms are machined at our facility in Portland OR, where we also do all design, assembly, testing, and support. Our in-house machine shop enables fast turnaround on repairs and service for our customer's vital production equipment. CDSS offers remote support for setup, maintenance and troubleshooting for all the machines we build at no additional cost.

If you are interested in Automated feeding and handling of loose parts, crimping, Automated seal plug insertion, or other fun mechanized toys be sure to check out our channel and our webpage @ www.CDavisSystems.com