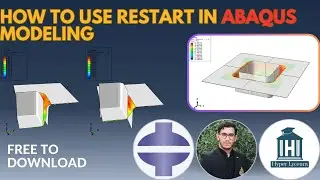

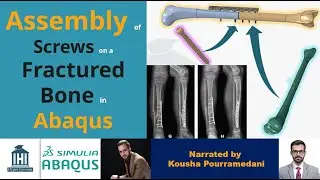

Abaqus Assembly of Screws on a Fractured Bone

In this tutorial, we use tibia bone and create the cortical and spongy parts. To do that we use the merge/cut option in Abaqus. This option enables us to place one component inside the other one which is very common in biomechanical simulation. To simulate the fracture, the bone gap is created. Then we assemble the plate and screw on the fractured bone. To place the screws we again use the merge/cut option. Finally, the tibia fractured bone model is assembled with implants and orthopedic screws. All the parts are modelled using CAD software and imported to Abaqus. Then, it is ready for analysis in Abaqus software.

In Abaqus software, when your finite element model consists of several parts or it requires the use of several parts, the Abaqus assembly module tools must be used to put these parts together. The tools of this module are very similar to the tools of CAD software assembly environments such as CATIA and SolidWorks. In fact, after applying the defined loads or initial conditions, the parts move and change according to the position that you have precisely specified in the assembly module. Using assembly module tools does not require academic knowledge and study and is merely a technical and experimental matter that with practice in this area, your ability to use these commands optimally will increase. In this video, some commonly used assembly module commands are explained in the form of a biomechanical example.

This video is less than 10 minutes and helps you to learn how to use Abaqus for this purpose. In this product, you can find the recorded video.

The video contents are:

0:00 Intro

0:46 Importing files in Abaqus

1:08 Using the merge/cut option in Abaqus

2:00 Creating a fracture in the bone

3:28 Assembly of the plate

4:06 Assembly of the screws

5:25 Finalizing the assembly

7:15 Ending

To download the part files please visit our website:

www.hyperlyceum.com

or the following link:

https://www.hyperlyceum.com/product/a...

This video is made by Saman Hoseini. For more information, please send him an email:

[email protected]