Dixon Valve & Coupling | 3D Printed Tooling & Fixtures

Markforged enabled Dixon Valve to produce new manufacturing tooling solutions faster and cheaper than ever before.

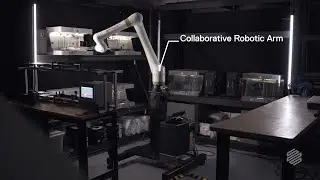

Dixon Valve uses Markforged 3D printers to manufacture End of Arm Tooling (EOAT) for their many robotic arms. With Markforged metal and composite 3D printers, Dixon Valve engineers eliminated the need to outsource or machine in-house the vast majority of their grippers.

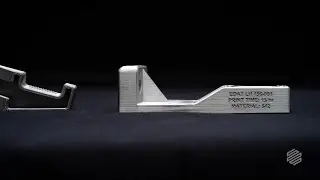

Dixon Valve 3D prints composite jaws that mount on a robot that transfers fittings between machining centers. They must survive corrosive fluids while subjected to repeated clamping forces.

They also printed specialized grippers jaws on the Metal X. These jaws, designed to hold fittings by their inside threads, needed to be hard enough to withstand the abrasion of threads while conforforming to the unique shape of the fixture.