3D Printing a Faster Manufacturing Floor | Zero Tolerance LLC x Markforged

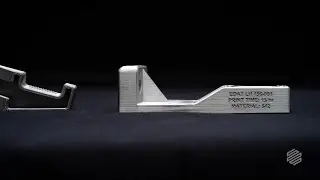

Steve Michon knew he had to improve a risky, time-consuming step in his company's injection molding process. But the cost and time it would take to automate was too prohibitive to everyday operations. Enter: Markforged.

With a one-time print - a simple, handheld tool he calls "the Claw" - Steve increased the output of his manufacturing floor by more than 50%, and made the molding process safer for his staff. Here's how he designed the part that transformed his business for the better.