VTC AUTOMATIC BAG HANDLING AND FILLING LINE

A fully automatic solution that offers resource efficiency, safety, and effectiveness.

Customized solution to pack all types of Powder & Granules material

Features:

• Fully automatic machinery minimizes human intervention.

• Excellent and reliable performance.

• A wide variety of feeders for various products.

• User Friendly machine handling tabs with PLC.

• Machines with sensors and alarms for trouble-free operation.

Description

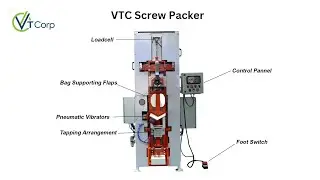

The Automatic Pick and Fill Sealing Machine is used for filling various types of solids and powders. The machine works automatically in picking, filling, and sealing of open Mouth Bags. It offers flexibility of using specific products with customized feeders.

We have customized the machine to pack all type of Powder & Granules material and currently worked for a Dry Wall Putty in Open Mouth Bags with the help of a robotic arm to pick the bags as a primary operation and then fill the material followed by stitching/sealing the bags which makes the machine fully automated, to make this process dust free for the good working environment we have provided a bag filter mechanism with the machine, and the comprises of the following:

1. Bag Magazine Conveyor for bag placement

2. Bag Separator to separate the loaded bags.

3. Bag transfer conveyor to transfer the separated bags to the coming operation.

4. Pneumatic bag opening mechanism to open the transferred bags and place them under the filling snoot.

5. VT Corp Impeller Packer (Open Mouth) to fill the bags with Dry Wall Putty.

6. Slatted Conveyors to displace the filled bags for bag sealing and stitching to bag discharge point.

7. Automatic Bag Sealer for sealing the inner liner of the bags with a cable tie.

8. Stitching/Sealing machine to stitch the outer covering of the bags.

This is a nonstop process independent of any force (manpower), saving the man hours cost and retired costs towards the unattended machine in absence of the operator being down for breaks.

It provides a pick and places mechanism for the bags from the stack, fills to dispense in the machine, hence Advantages of Automation in Packaging:

1. Lower Operating Cost

2. Assured Productivity

3. Better Packing Quality

4. Greater Consistency

5. Faster ROI

6. Reduces Dependency on Manpower

7. Improved working conditions making it most suitable and essential in GMP (Good Manufacturing Practice).

In conclusion, automation must be coupled with changes in the mortal terrain of a company.

For more details:

Visit us at http://www.vtcorpindia.com/

Mail us at: [email protected] / [email protected]

Or give us a WhatsApp/Call at: 9920341119

Corporate Office:

901 Windfall Building, Sahar Plaza Complex, MV Road, J B Nagar, Andheri East, Mumbai, Maharashtra 400059, India

#packagingindustry #packagingsolutions #packaging #pfs

#bagging #food #foodandbeverageindustry #agro #chemicalindustry #chemical #building #buildingmaterials #powder #granules #fmcg #liquidpackaging #vtcorp